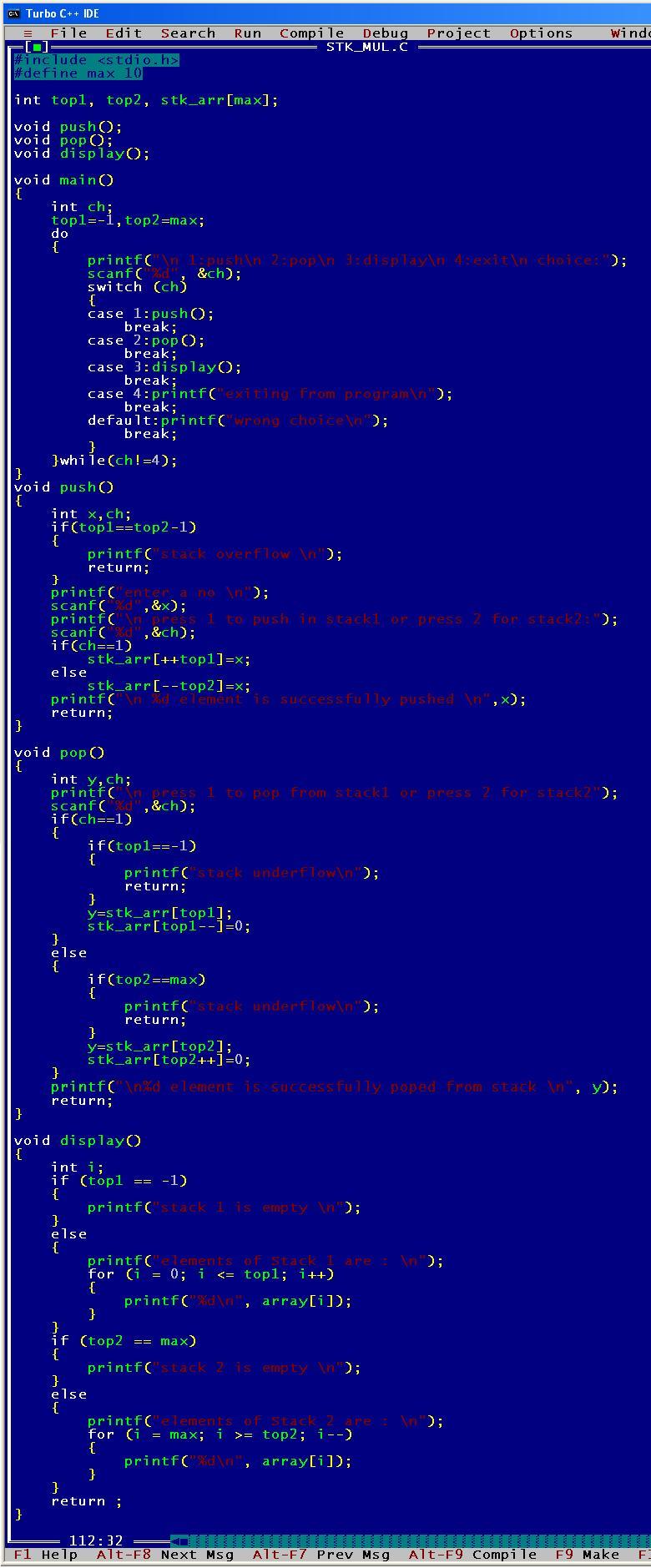

C Program For Queue Operations Using Arrays

The term operations management encompasses planning, implementing, and supervising the production of goods or services. Operations managers have responsibilities in both strategy and day-to-day production, in either manufacturing or services. Sometimes called production management, the field is cross-functional, tying in with other departments such as sales, marketing, and finance. It’s involved in product or service creation, development, production, and distribution. In effect, it connects dots along the value chain. Technology, ever changing, plays a key role in springboarding constant advancements in operations management (OM). That’s truer now than ever before thanks to budding advancements like self-maintaining smart machines (for production) and drones (for distribution).

Nov 10, 2012 Sample output: >>>c program to implement queue operations queue 4.Empty Descarga Gratuita Windows Vista Ultimate. queue. C program for queue using array. Queue is a data structure which works as FIFO principle. FIFO means 'First in First out', i.e the element which we.queue.

Companies that use technology well can thrive, and those that don’t may not survive. “The future of operations management is going to involve increasing automation to the point that we will hardly recognize the way new organizations function,’’ says Iris Tsidon, Co-Founder and CEO of, a cloud-based key performance indicator (KPI) platform. This article will provide an overview of operations management: its history, importance, functions, strategies, principles, and types of production.

You’ll also hear from seven operations management professionals about tips, challenges, trends, and the future. Deeper Definitions: What Does Operations Management Mean?

In its broadest sense, operations management is responsible for all aspects of creating goods and services. It manages resources such as materials, machines, technology, and people, and makes products and services that the marketplace wants. Emotional Intelligence Daniel Goleman Pdf. The whole chain of events must be well managed for a business to be competitive. As we define operations management more fully, we consider these foundations of OM: • Planning: Operations managers must constantly forecast, plan, and adjust to optimize processes based on conditions. • Process: Production of goods or services requires having strong, repeatable processes. • Efficiency: Managers must troubleshoot bottlenecks, inadequate resources, and downtimes to create optimal efficiency.

• Cost Control: Production is typically a major part of a company’s cost structure, and you must manage it wisely. • Quality: Good quality control is necessary to maintain customer satisfaction and the company’s reputation. Companies can greatly suffer without it. • Continuous Improvement: To remain competitive, companies need to have processes in place to consistently seek better ways of doing things. • Technology: Underlying all of these foundations is technology. Well-used technology keeps a company ahead of the curve.